Poultry & Livestock Automation & Monitoring

Neum Technologies’ Livestock Automation Systems transform traditional farming into intelligent, data-driven environments. Our IoT-powered platforms continuously monitor key environmental parameters such as temperature, humidity, ammonia (NH₃), and CO₂ levels, ensuring optimal living conditions around the clock. Through automated feeding, watering, and precise climate control, livestock receive exactly what they need, when they need it — minimizing waste and maximizing growth. Integrated lighting management and ventilation control maintain consistent microclimates, while real-time health monitoring features adapt operations ahead of changing conditions. By optimizing heating, cooling, and resource use, Neum’s systems help farmers achieve higher productivity with lower operational costs, supporting both profitability and animal welfare.

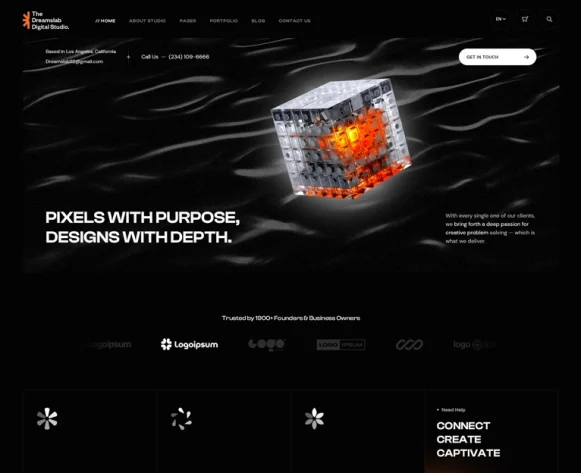

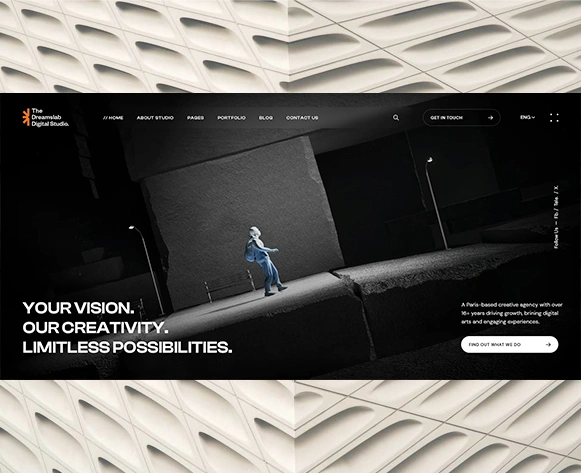

SMART POULTRY & LIVESTOCK AUTOMATION FOR OPTIMAL HEALTH & EFFICIENCY

Our automated livestock solutions ensure a healthier flock and higher productivity by maintaining precise environmental control. From regulating temperature and air quality to automating feeding schedules, our systems reduce mortality rates and operational costs while maximizing growth.

PRECISION CLIMATE CONTROL

Monitor and automatically adjust temperature, humidity, and ventilation in real-time. Ensure optimal conditions for bird comfort and health, reducing stress and mortality rates significantly.

AUTOMATED FEEDING & WATERING

Streamline nutrition delivery with automated schedules that ensure consistent access to feed and water. Eliminate waste, save labor costs, and promote uniform growth across your flock.

AIR QUALITY & AMMONIA

MONITORING Protect your livestock from harmful gases with continuous ammonia (NH3) and CO2 monitoring. Our systems trigger ventilation automatically to maintain safe, breathable air quality.

REAL-TIME HEALTH ALERTS

Stay informed with instant notifications on your mobile device. Detect issues like equipment failure, temperature spikes, or low water levels immediately to prevent losses before they happen.

services included

and reduce mortality rates—resulting in a more profitable and sustainable operation.

Custom Smart Barn Design & Upgrades

Tailored automation retrofits or new smart barn designs optimized for local weather conditions, ensuring scalability and biosecurity.

- Optimizes ventilation and temperature for maximum bird comfort.

- Integrates automated feeding and watering lines seamlessly.

- Ensures efficient energy use with smart lighting and heating control.

- Enhances biosecurity through automated access and environmental monitoring.

Automated Climate & Ammonia Control

Intelligent systems that automatically regulate fans, heaters, and cooling pads based on real-time sensor data to maintain safe air quality.

- Monitors and controls Temperature, Humidity, and CO2 levels.

- Detects and reduces harmful Ammonia (NH3) concentrations automatically.

- Prevents heat stress and respiratory issues in livestock.

- Reduces energy waste by operating equipment only when necessary.

Remote Monitoring & Analytics

Stay connected to your farm 24/7 with our mobile app and web dashboard, providing instant alerts and data-driven insights.

- Real-time visibility of farm conditions from any smartphone or PC.

- Instant SMS/App alerts for power failures, temperature spikes, or equipment faults.

- Historical data analysis to track growth cycles and feed efficiency.

- Centralized management for multiple sheds or farm locations.

Driving Real Results with Innovation, Insight, and Sustainability

Unlock measurable impact with advanced technology, proven methodology, and dedicated support—every step designed to accelerate your growth and optimize outcomes.

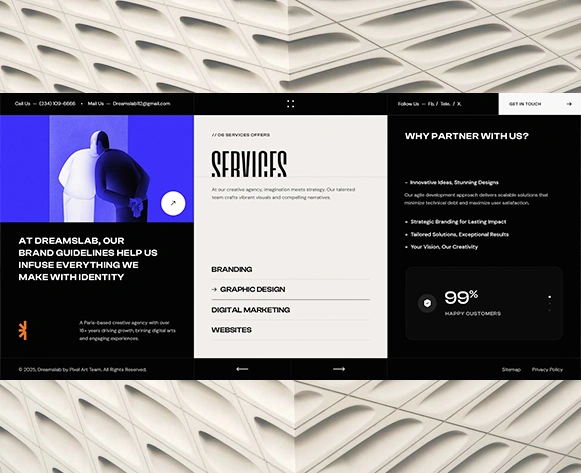

Solution-Centric

Innovation

We harness the latest in IoT and automation, creating transformative solutions that address your unique challenges and set you apart in your industry.

Collaborative

Development

From vision to deployment, our team works closely with you—aligning technology, strategy, and execution for maximum value and seamless integration.

Data-Driven

Excellence

Every stage is guided by powerful analytics and actionable insights, ensuring decisions are based on real data for sustained, measurable success.

Unwavering

Reliability

Our solutions are engineered for robustness, security, and scalability—supported by dedicated experts to guarantee high performance, 24/7.

Transparent

Communication

Experience open, honest dialogue through every phase—so your goals, feedback, and success always come first in our partnership.

Poultry & Live Stock Automation

Live Sensor Monitoring:

🌡️ Temperature: Real-time barn temperature readings (e.g., 28.5°C).

☣️ Ammonia (NH3): Monitors harmful ammonia levels in ppm (parts per million). This is critical for bird health.

☁️ CO2 Levels: Tracks Carbon Dioxide buildup to ensure air quality.

💧 Humidity: Displays relative humidity percentage.

🌽 Feed Level: Shows the remaining feed quantity in the silo/hopper.

Interactive Controls:

🌽 Feed Button: Manually triggers the feed lines to drop pellets (chickens will run to eat).

💨 Vent Button: Activates the tunnel and exhaust fans to lower temperature, Ammonia, and CO2.

🔥 Heat Button: Turns on the heater to raise the barn temperature.

💡 Light Button: Toggles the barn lights and switches the outside environment between Day and Night.

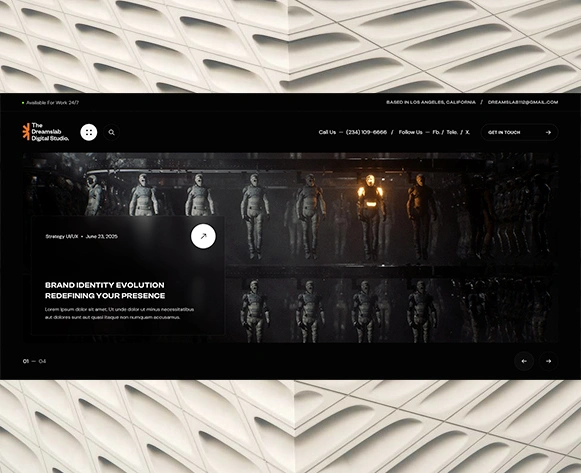

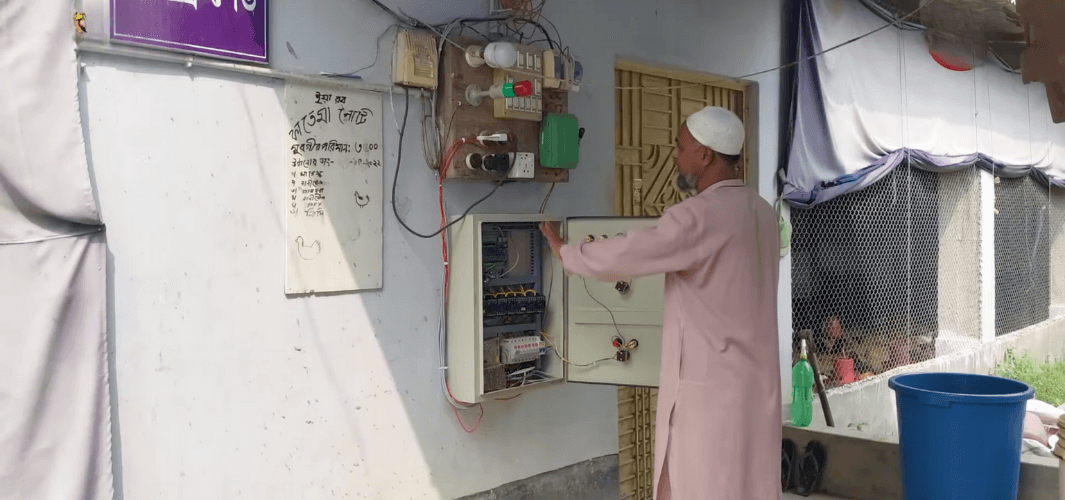

glimpse of projects

Client Success Stories

See how forward-thinking organizations are transforming their operations with smarter technology, data-driven insights, and seamless automation for measurable impact and sustainable growth.

JAKAS Foundation

Efficiency Through Smart Technology