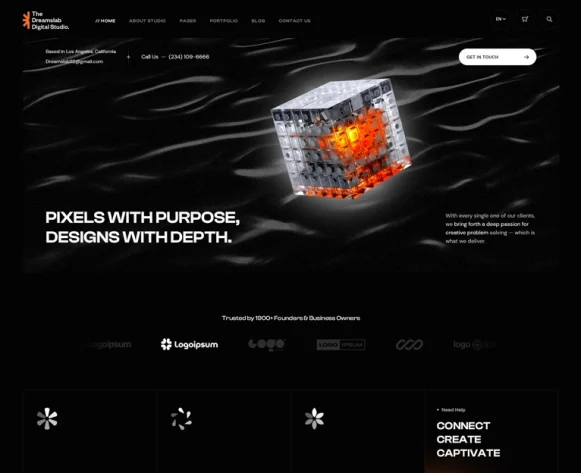

SMART AQUACULTURE AUTOMATION & MONITORING

Neum Technologies’ Aquaculture Automation Systems bring precision and intelligence to fish and shrimp farming. Our IoT solutions continuously monitor critical water quality parameters—Dissolved Oxygen (DO), pH, Ammonia, and Temperature—ensuring a healthy aquatic environment 24/7. Automated aeration and feeding systems respond instantly to real-time data, reducing feed waste, lowering energy costs, and preventing mass mortality events. With remote monitoring via our mobile app, farmers gain total control and data-driven insights to maximize yield, improve sustainability, and secure their harvest against unpredictable conditions.

SMART AQUACULTURE AUTOMATION FOR BETTER UNDERWATER LIFE

We provide a comprehensive aquaculture automation suite designed to stabilize water quality, automate critical tasks, and boost production efficiency. Our integrated solutions ensure your aquatic environment remains optimal around the clock, reducing operational risks and maximizing profitability.

Custom RAS & Pond Automation Design

Monitor and automatically adjust temperature, humidity, and ventilation in real-time. Ensure optimal conditions for bird comfort and health, reducing stress and mortality rates significantly.

Automated Water Quality & Feed Management

Streamline nutrition delivery with automated schedules that ensure consistent access to feed and water. Eliminate waste, save labor costs, and promote uniform growth across your flock.

Remote Monitoring & Data Analytics

MONITORING Protect your livestock from harmful gases with continuous ammonia (NH3) and CO2 monitoring. Our systems trigger ventilation automatically to maintain safe, breathable air quality.

INSTANT MOBILE ALERTS

Stay informed with instant notifications on your mobile device. Detect issues like equipment failure, temperature spikes, or low water levels immediately to prevent losses before they happen.

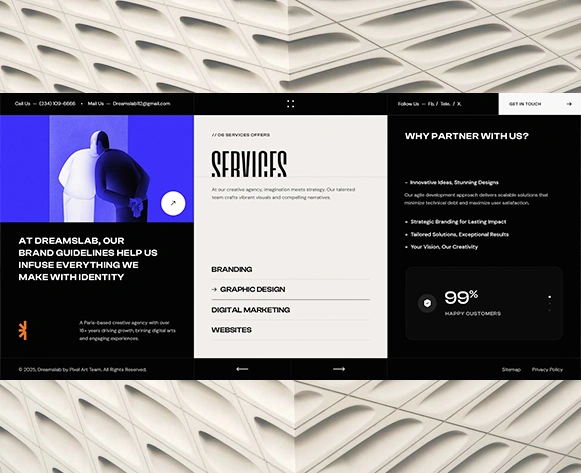

services included

By continuously tracking critical parameters and automating essential functions, we help you reduce mortality, lower feed costs, and achieve sustainable, high-yield harvests.

Custom Pond & Tank Automation Design

Tailored automation setups for ponds, biofloc tanks, or hatcheries, designed to withstand humid and aquatic environments while optimizing space and energy.

- Designs scalable for everything from small ponds to industrial Recirculating Aquaculture Systems (RAS).

- Integrates automated aeration and feeding infrastructure seamlessly.

- Uses corrosion-resistant materials and waterproof enclosures for longevity.

- Optimizes layout for efficient water flow and waste removal.

Automated Water Quality & Feeding Control

Smart systems that automatically regulate aerators, pumps, and feeders based on real-time sensor data to maintain a stable, healthy ecosystem.

- Monitors and controls DO (Dissolved Oxygen), pH, Temperature, and Ammonia levels.

- Automatically activates aerators when oxygen drops, saving energy.

- Precision feeding based on schedules or appetite reduces Feed Conversion Ratio (FCR).

- Maintains optimal water levels and filtration automatically.

Remote Monitoring & Predictive Analytics

Monitor your entire aquaculture operation from anywhere with our cloud-based platform, receiving instant alerts and actionable insights.

- 24/7 real-time visibility of all water parameters on your mobile device.

- Instant alerts for critical events like power failure, low oxygen, or pump malfunction.

- Data trends and reports to help predict growth rates and harvest times.

- Centralized dashboard to manage multiple ponds or tanks simultaneously.

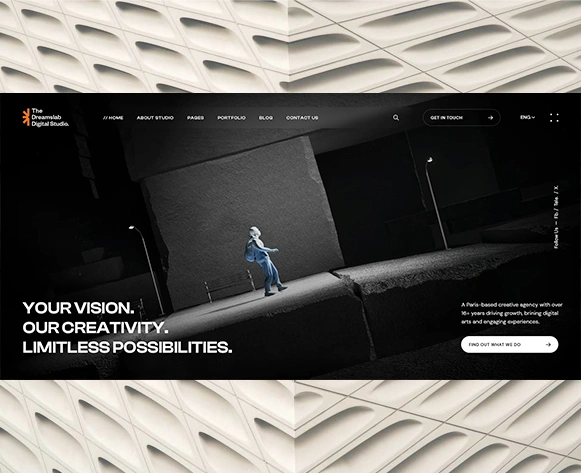

Driving Real Results with Innovation, Insight, and Sustainability

Unlock measurable impact with advanced technology, proven methodology, and dedicated support—every step designed to accelerate your growth and optimize outcomes.

Solution-Centric

Innovation

We harness the latest in IoT and automation, creating transformative solutions that address your unique challenges and set you apart in your industry.

Collaborative

Development

From vision to deployment, our team works closely with you—aligning technology, strategy, and execution for maximum value and seamless integration.

Data-Driven

Excellence

Every stage is guided by powerful analytics and actionable insights, ensuring decisions are based on real data for sustained, measurable success.

Unwavering

Reliability

Our solutions are engineered for robustness, security, and scalability—supported by dedicated experts to guarantee high performance, 24/7.

Transparent

Communication

Experience open, honest dialogue through every phase—so your goals, feedback, and success always come first in our partnership.

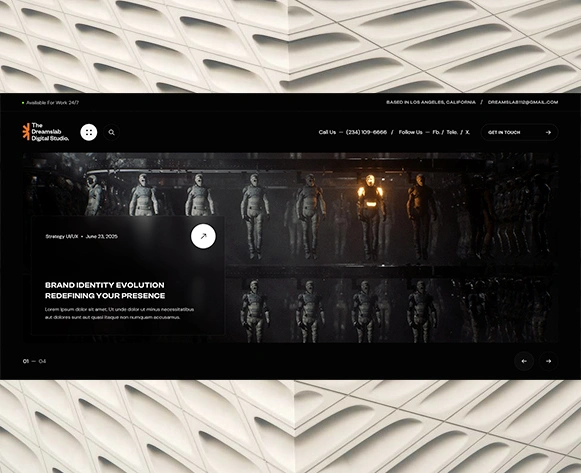

Aerator Control and Automation

Features & Facilities in the Smart Aquaculture Automation Demo:

Real-time Sensor Data: Live monitoring of critical water parameters:

🫧 DO (Dissolved Oxygen): Monitored in mg/L

🌡️ Temp: Water temperature in °C.

🧪 pH: Acidity/Alkalinity level.

☣️ NH3 (Ammonia): Toxic ammonia levels in mg/L.

Interactive buttons to toggle equipment:

🌽 Feed: Dispense food.

🫧 Aerator: Turn aeration on/off.

🔄 Pump: Turn the water pump on/off.

💡 Light: Switch between Day and Night modes.